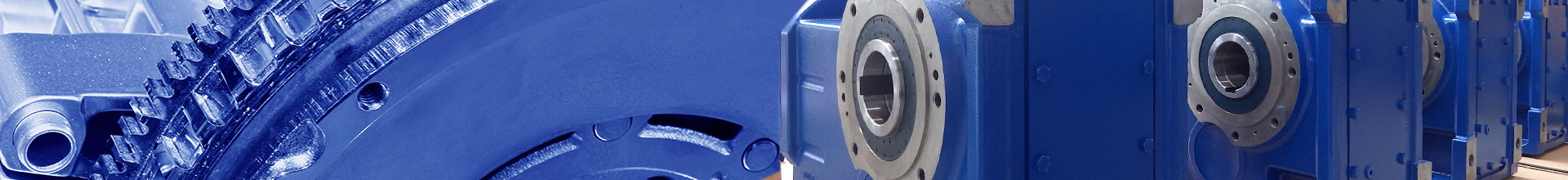

Service of gearmotors

We perform periodic

inspections of gear transmissions, seal replacement, oil service,

repairs and replacements of couplings. We conduct a complete technical

analysis and diagnostics of all elements of the gear.

inspections of gear transmissions, seal replacement, oil service,

repairs and replacements of couplings. We conduct a complete technical

analysis and diagnostics of all elements of the gear.

Benefits:

- Restoration of the full functionality of the drive

- Report from the performed servicing operations

- Operating Precautions - ensuring the long and trouble-free operation of the drive to the user

- 12 month warranty - certainty of reliable operation after the performed service

Diagnostics of gearmotors

- Full control of the efficiency of electrical circuits of the motor and the circuits of the additional equipment

- Measurement of the winding resistance and condition of insulation

- Measurement of idle and under load currents

- Control of built-in motor sensors

- Checking of the oil level sensors

- Checking of the lubrication and cooling system, control of leakages.

- Checking the condition of the bearings.

- Measurements of shaft alignment and vibration levels

- Measurements of axial and radial clearances

- Measurement of the body temperature

- Ad hoc vibration measurements and long-term periodic vibration diagnostics surveillance of the gearmotors

- Inspection of the brake linings, control of the assembly of the remaining additional equipment of the motor and the reducer

- Control of the tightness of the seal between the gear unit and the motor.

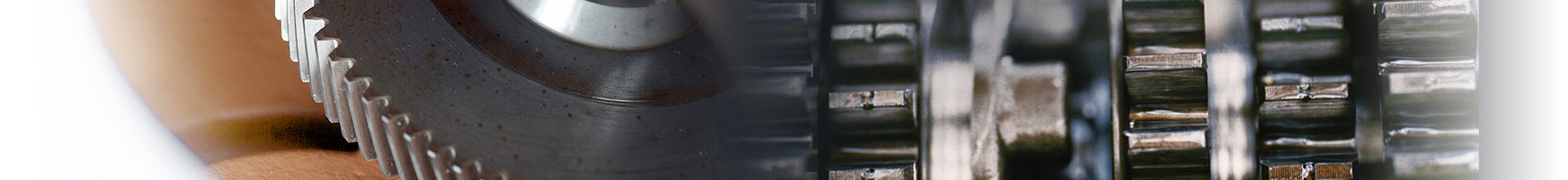

- Control of the wear of the internal components of the gear, wear of the cogs, toothed shafts, etc.

- Control of the tightness of the cooling circuits and the gear lubrication circuits.

Renovations of gearmotors

- Oil service, oil change at the client`s premises and in the company`s workshop

- Replacement of components of the gears, bearings, cogs, shafts, seals

- Shaft regeneration

- Repairs or replacement of motors

- Coupling drilling and mounting

- Repair and cleaning of the lubricating and cooling circuits

- Renovation of the paint coating